|

PROJECT FACTS |

|

|

Vessel: |

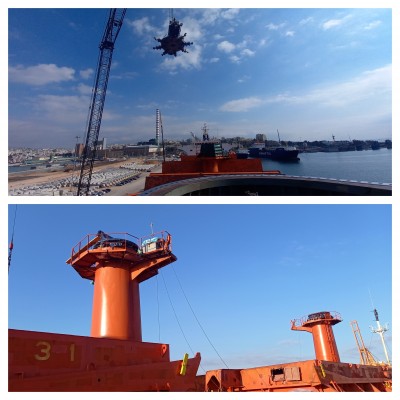

M/V Nueva Fortuna |

|

Type: |

Bulk Carrier |

|

Tonnage: |

50992 DWT |

|

Location: |

Perama, Greece |

|

Foundation diameter: |

2800 mm (approx.) |

|

No of surfaces: |

4 fixed posts + 4 slewing posts |

|

Flatness Tolerance on surface: |

0,15mm/ 2800mm |

|

|

|

Damage / problem encountered:

I.PANTACHOS- A. VENTOURIS S.A. received an enquiry from FAFALIOS SHIPPING S.A. to perform several in-situ machining repairs related to the vessel’s Cranes.

More specifically, after dismanting of the Crane slewing posts had taken place, all slewing bearing seats in both fixed and slewing posts were damaged.

As a result, they had to be machined in-situ.

Our company quickly responded to the enquiry, discussed the job’s scope and repair procedures with the Company’s technical representative and was promptly awarded the job.

We immediately started the preparations and modifications needed to carry out the requested repairs.

Rectification process followed:

Fixed posts:

Set up & alignment of the special, custom engineered orbital milling machine on each of the 4 crane fixed posts.

Milling of the bearing seat in order to establish a fine and flat surface (according to maker specifications).

Slewing posts:

Set up & alignment of the special, custom engineered orbital milling machine, on each of the 4 crane slewing posts.

Milling of the bearing seat in order to establish a fine and flat surface (according to maker specifications).

Depending on the requirements, our versatile & modular equipment can be modified so as to perform milling of flanges greater than 3m in diameter and achieve tight tolerances.

It can be used in Crane slewing bearing seats, Wind turbines and other offshore & on shore projects.